What Are Absorbent Pads and Rolls?

Absorbent Pads & Rolls

Absorbent pads and rolls are part of the products range used for oil and chemical spills clean-ups. Different from household tissue wipes, they offer better durability and absorbency. They come in different shape and form and have several primary uses: absorbing leaks around machinery, soaking up spills, and serving as a lining. In this article, we will further explain the similarities and differences between absorbent pads and absorbent rolls before your next purchase.

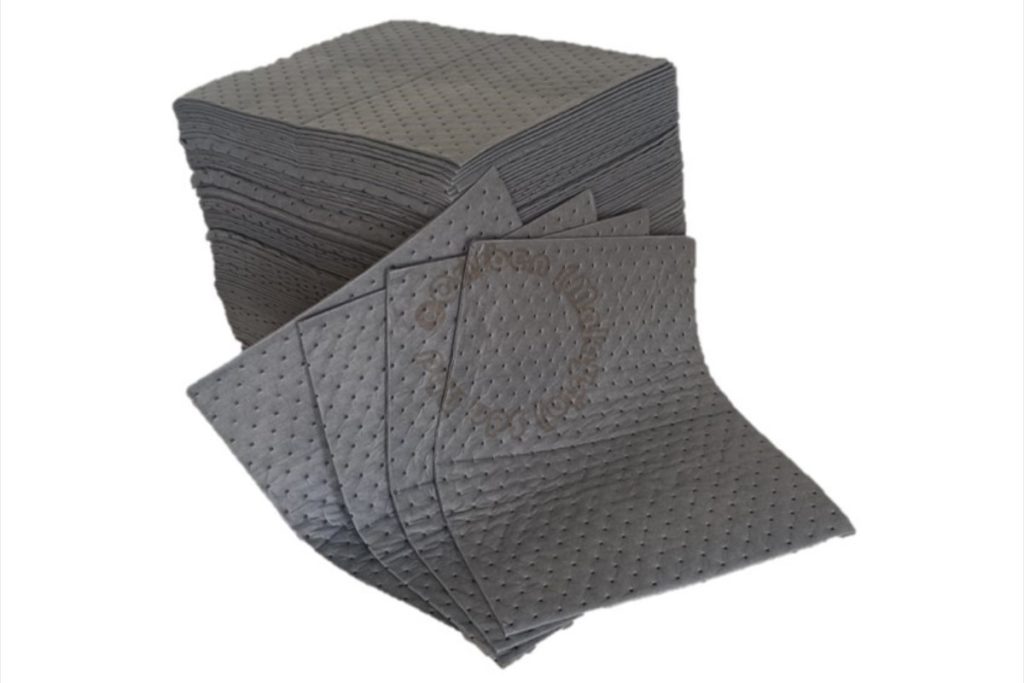

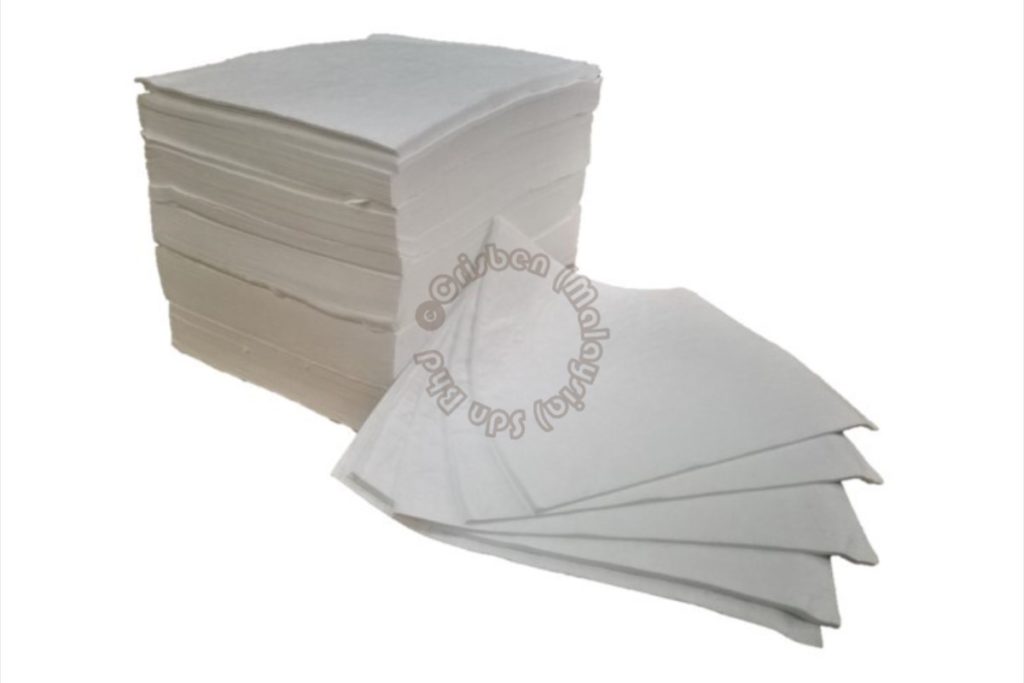

Both absorbents are made of polypropylene. Absorbent pads are rectangular, pre-cut shape that makes them covenient to deploy in various locations and situations. These pads are commonly used in spill kits, production areas, and servicing areas.

Crisben absorbent rolls have a continuous length of 50 meters. They are typically used as linings under machinery to capture leaks, drips, or spills during operation. Some absorbent rolls have a plastic lining underneath to prevent absorbed liquid from leaching out and staining the floor.

There are 2 available thickness (GSM); 200gsm and 400gsm. Before choosing the thickness suitable for your needs, you might want to consider the expected volume of liquid spills at your location. For small or thinly spread spills, 200 gsm pads are ideal. For larger volumes in a confined area, opt for the 400 gsm pads.

Absorbent pads and rolls have two different types each; Dimpled and Non-Woven

If you primarily use the pads or rolls for wiping/high abrasion activities, the dimpled type is highly recommended. If used solely for absorbing and clean-ups(padding or lining), the non-woven type is preferable.

In addition to spill clean-up, absorbent pads and rolls assist with daily operations involving liquids that have the potential to spill. Compared to regular rags, one box of Crisben’s absorbent pads and rolls can absorbs spillages up to 110 liters. This is the best, cost-saving solution in both clean-up and waste disposal comparing to other conventional absorbents.